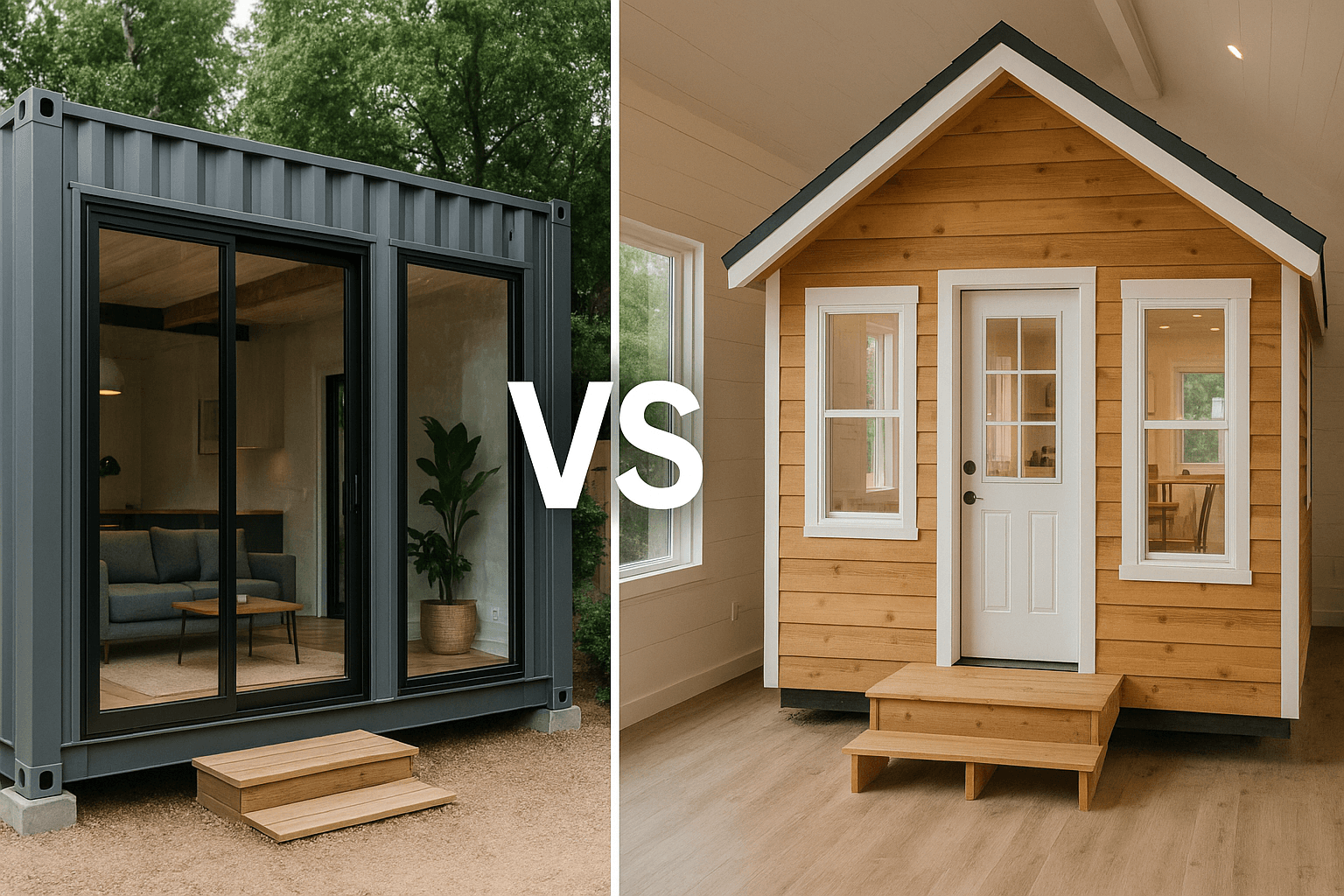

Tiny House vs Container Home 2026: Cost, Construction & Materials

Shipping container homes and tiny houses both offer alternative housing at similar costs and sizes. Containers provide industrial style using recycled materials. Tiny houses use traditional wood framing with residential finishes. This guide compares construction methods, costs, insulation challenges, and which works better for different goals.

TLDR: Tiny House vs Container Home

Both cost $30,000-$100,000 for similar-sized dwellings

Containers require expensive insulation and rust treatment to be livable

Tiny houses use standard construction methods familiar to most builders

Containers need welding and metal-cutting skills, tiny houses need carpentry

Both face similar zoning restrictions and require building permits

Construction time is comparable (3-6 months) for either option

Metal containers create condensation and thermal bridging problems that cost thousands to solve properly

Container costs vary widely based on modifications. Research insulation requirements thoroughly before purchasing.

Shipping container homes gained popularity in the 2010s as a sustainable housing solution using recycled materials. The appeal is strong. Containers are everywhere, relatively cheap to buy, and provide instant structure. They look modern and industrial. Many people see them as a shortcut to affordable housing.

However, converting containers into comfortable homes requires extensive work. Metal containers were designed to ship goods, not house people. Making them livable means solving insulation challenges, cutting structural steel carefully, treating rust, and adding windows and doors. The total work often costs as much as building a tiny house from scratch.

This comparison looks past the hype to examine real costs, construction challenges, and whether containers actually save money compared to traditional tiny house construction. Both options work, but they suit different goals and builder skill sets.

Cost Comparison

Container Conversion Cost Breakdown (40ft Container)

| Item | Cost Range | Notes |

|---|---|---|

| 40ft Container | $3,000-$7,000 | 320 sq ft interior |

| Doors & Windows | $1,500-$4,000 | Cutting + reinforcement |

| Rust Treatment & Paint | $1,000-$3,000 | Essential for durability |

| Spray Foam Insulation | $2,000-$5,000 | All surfaces required |

| Interior Framing | $1,500-$3,000 | For drywall attachment |

| Plumbing & Electrical | $3,000-$8,000 | Full systems |

| Flooring | $1,000-$3,000 | Over metal floor |

| Kitchen & Bathroom | $3,000-$10,000 | Fixtures & cabinets |

| Total Container Build | $28,000-$67,000 | $88-$209/sq ft |

Side-by-Side Cost Comparison (300 sq ft)

Container Home (320 sq ft)

- Base Container$3,000-$7,000

- Conversion Labor & Materials$25,000-$60,000

- Structural Engineering$1,000-$3,000

- Total Cost$29,000-$70,000

- Per Square Foot$91-$219/sq ft

Tiny House (300 sq ft)

- Trailer Foundation$8,000-$12,000

- Construction (DIY)$17,000-$48,000

- OR Professional Build$67,000-$108,000

- Total Cost (DIY)$25,000-$60,000

- Per Square Foot (DIY)$83-$200/sq ft

The Hidden Container Costs

According to Container Home Hub, while containers seem cheap ($2,000-$7,000), conversion costs add up quickly. The per-square-foot cost ends up similar to tiny houses. Containers don't save money unless you do most work yourself and own welding equipment. Tiny houses from professional builders often cost less because standard trades can complete the work.

Construction Methods and Skills

Required Skills & Tools Comparison

| Aspect | Container Home | Tiny House |

|---|---|---|

| Primary Skills | Metal-working, welding, cutting steel | Basic carpentry, wood framing |

| Special Tools | Plasma cutter, welder, torches | Standard carpentry tools |

| Contractor Availability | Limited, expensive specialists | Widely available carpenters |

| DIY Difficulty | Advanced (steep learning curve) | Moderate (common skills) |

| Construction Timeline | 3-6 months (if skilled) | 3-6 months (standard) |

Container Challenges

- Requires specialized welding skills

- Few contractors have container experience

- Cutting weakens structural integrity

- Premium rates for specialized expertise

Tiny House Advantages

- Any carpenter can build tiny houses

- More contractors = competitive pricing

- DIY-friendly with common tools

- Standard construction methods

Insulation and Climate Control

This is where container homes face their biggest challenge. Metal conducts heat and cold extremely well. An uninsulated container becomes an oven in summer and freezer in winter.

Container Insulation Problems

- Thermal bridging: Heat moves through the metal despite insulation

- Condensation: Warm interior air hitting cold metal causes moisture buildup

- Mold risk: Trapped moisture leads to mold and rust deterioration

- Space loss: Proper insulation reduces interior dimensions by 4-8 inches on all sides

Spray foam insulation costs $2,000 to $5,000 for a single container. You need at least R-13 to R-19 on walls and R-30 on the roof for comfortable year-round living.

Tiny House Insulation Advantages

- Designed with proper insulation from the start

- Wall cavities accommodate R-13 to R-21 without reducing interior space

- Standard construction allows vapor barriers and ventilation

- Climate control is simpler and cheaper

According to U.S. Department of Energy research, properly insulated tiny houses use 60 to 80 percent less energy than standard homes. Containers use more energy due to thermal bridging through the metal structure even with insulation.

Zoning and Building Permits

Container homes and tiny houses face similar zoning challenges. Both are non-traditional housing that some jurisdictions restrict. Neither gets special treatment just because they use alternative construction methods.

Key Zoning Considerations

- Some cities specifically ban shipping containers for residential use

- Both need building permits in most areas

- Containers must meet the same codes as stick-built homes

- Container plans often require structural engineering stamps ($1,000-$3,000)

- Tiny houses on foundations can qualify as ADUs in many jurisdictions

Before choosing either option, research your local zoning laws carefully. Use our Zoning Finder to check regulations in your area.

Which One is Right for You?

Choose a Container Home If:

- You love industrial modern aesthetics

- You have welding/metal-working skills

- You want an architectural statement

- You can handle insulation challenges

- You want to use recycled materials

Choose a Tiny House If:

- You want standard construction methods

- You need better insulation & efficiency

- You prefer traditional home finishes

- You want easier contractor availability

- You want easier resale to broader pool

Design vs. Practicality

Both options create unique small homes. The choice depends on your aesthetic preferences, construction skills, and willingness to handle container-specific challenges. Browse tiny house listings to see what is available, or read our complete buyer's guide to understand the full tiny house purchase process.